In this quick guide, we want to prime you on Lean Operations Management. We will not talk only about lean operations, but also about how to manage it. If you are an operations manager, or work in any other type of operations (e.g., contact centers, IT operations, and so on), then this guide is for you.

We will first discuss what lean operations is, and then go deeper into lean operations management. If you already know lean operations in itself, feel free to jump directly to the second part.

Lean Operations

Introducing Lean

Lean is a philosophy of approaching any production process, not necessarily manufacturing. It can apply to production in the sense of producing a car on an assembly line, which is typical, but also in more abstract ways. For example, we can consider “production” the process of creating a beautiful PowerPoint for your presentation: lean can apply there too.

The lean philosophy is simple. It tells us that we should strive to deliver perfect quality, in exact quantities, exactly where and when needed, and at low cost. In short, it tells us there is no room for imperfection.

Since lean does not tolerate imperfections, the most natural way of implementing lean is by simply looking around what you are doing and remove imperfections. Then, look again and find other imperfections, and remove them too. This process repeats indefinitely, as there will be always better ways to do things (particularly as technology continues to progress), so for lean there is not an end state that can be reached to stop improvement. That state is like the horizon, elusive, the more you get close to it, the more you realize it is actually further away.

Since we keep looking for imperfections to fix and things to make better, we often call lean continuous improvement, because we relentlessly keep improving. Also, by its nature, this improvement is incremental: a set of many small steps, no big leaps. The idea is to find an imperfection in the process that is reasonable to think it can be fixed, and then fix it.

Lean is not the only approach to make your production process more effective. There are other approaches such as Six Sigma (relying heavily on statistics) or Business Process Reengineering (preferring disruptive changes rather than continuous improvement). Today we are talking about lean, but before putting anything to action you should also explore the other tools and see which one is better for you.

Lean Operations

Before we can talk about lean operations management, let’s talk about lean operations by themselves. It is no secret that by “Lean Operations” we intend operations that are adopting the lean philosophy, but what does it mean exactly?

Operations is the set of activities that a business use to deliver its products and services. It is whatever you are doing to produce what you are selling, be that a car, an oil rig, or a lengthy contract (in case of a law firm). Operations is one of the three key functions of any business, with the other two being marketing and sales, and product development. In addition, companies tend to have support functions such as finance, IT, or HR.

Applying lean to operations means thinking “how can we be more effective at producing our product or delivering our service?”. Since lean is about continuous improvement, it is about asking this question over and over indefinitely, always tweaking with operations to make it better.

This, in turn, means be willing and able to change your projects slightly and accept that over time they may become quite different from where they started from. For example, you may realize that time is wasted to carry parts from one area of your factory to another, and move the two production station closer so that there is less time to move parts between them. This can seem like a small thing, but over time it can save a lot of time and, thus money. Even the implementation may not be trivial, because you may need to move equipment which is heavy and may be made of many components that need to be disassembled and reassembled.

Operations are a process, where worker, machines and technologies work together to get something done. Lean operations means thinking about how this process can be made better, rearranging activities, workers, and technologies to be faster, better, or both.

The Key Pillars of Lean

By now, we know the idea behind lean operations, and this will help us when discussing lean operations management. However, this philosophy has some common-sense actions that always tries to perform, and knowing them in advance can be a powerful mental shortcut.

The lean operations developed in the Toyota factories after WWII out of a need to do “more with less”, as you probably know. It is no surprise that much effort of lean activities was designed to reduce waste: wasted materials, wasted time, unproductive activities, and so on.

- Irregular flow – waste can arise because of waiting time, transport, or unnecessary motions performed by employees when doing the work.

- Inexact supply – waste arises from overproduction, because then inventory is left idle waiting to be processed, or for underproduction, because then machines are left idle waiting for their input. It can also arise because early or late inventory delivery, which has the same effect.

- Inflexible responses – waste can arise from large batches of work, delay between activities, or variation in activity mix (changing frequently between what you are doing).

- Variability – Unreliable equipment and defective products can cause waste as well.

Lean is also obsessed with inventory reduction. Inventory is stock of product that is waiting for something: finished product waiting to be sold, raw materials waiting to be processed, and so on. The idea behind this is simple: to build up inventory, you have to spend money (for example buying raw materials). However, until you sell the product, you don’t see your money back – they are absorbed in the production. Thus, the more inventory you have, the more it drags on your cash. You should reduce it as much as possible.

The idea of reducing inventory goes hand-in-hand with just-in-time (JIT) manufacturing. Since you have little inventory, you need to coordinate the production processes so that the output of a process that acts as an input for the next one is produced just in time for when the next process will need it. Hence, the pace of the production is set by processes downstream, that “demand” input from other processes and thus set their pace. This is known as pull, where push is just producing as much as you can and build inventory.

Most people fail to notice the true spirit of lean operations, and this became evident as part of the supply chain disruptions during COVID-19 pandemic. Lean is not about reducing inventory at all costs, it is about reducing waste: inventory can be a waste, but it isn’t necessarily. With little or no inventory, the company has no room for failure and limited flexibility. If flexibility and resilience is something important for your company, inventory can become an asset.

Lean Operations Management

Now that we addressed the key concepts of lean operations, we can dive deeper into lean operations management: how to manage a lean operation. In this section, we will see some management levers you can use to run lean operations effectively.

Identify the Sources of Waste

The first step in lean operations management is to identify the sources of waste and try to reduce them. This is done by observing the production process, but you have to pay close attention because things are often not so evident at the beginning.

In the introduction covering lean operations, we discussed that waste could originate from irregular flow, inexact supply, inflexible responses, or variability. However, there are the main areas of waste, knowing what can actually be wasted will help you to know where to look:

- Resources can be wasted as they are unnecessarily scrapped, or they are held in inventory for longer than needed. Resources can materials, but also cash.

- Motion, which is the collection of physical movement of workers, can be wasted by doing unnecessary move or too complex moves.

- Time can be wasted waiting for resources, materials, processes, and so on.

- Equipment can be wasted by keeping it idle to wait it to process resources. This could fall into the “resources” bucket, but it is important to keep an eye specifically on equipment, therefore we decided to list it separately.

- Customers can be wasted, by not servicing their request or by having product out of stock when they would have wanted to buy. In general, this represents a wasted opportunity.

With these five types of waste, you can start to have a clear idea about what you need to look for. Any company will always have some waste in all categories, because full perfection is never truly reached, and the bar can always be raised.

Once you have identified some waste that is actually in place in your operations, lean operations management wants us to get back to the root cause. Find the symptoms, then go deep to find the cause.

Find the Root Cause of Waste

Imagine you identify a cause of waste, such as customers being turned away because there is no product for them, and you are out of stock. In this case, the waste is the foregone opportunity to make a sale. Lean operations management wants us to ask “why?” as many times as needed, until we get the root cause.

Of course, asking “why?” is not enough. You need to come up with good answers, and this involves collecting measurable data. Nonetheless, a “why” analysis in lean operations management can look like this:

- Why are we foregoing sales? Because we are out of stock in multiple supermarkets.

- Why are we out of stock in multiple supermarkets? Because the shipment does not cover the full week in most cases?

- Why the shipment does not cover the full week? Because the supermarket set their order quantity low.

- Why supermarket set their order quantity to low? Because the product is expensive and perishable, if it expires, they will incur in a loss and they prefer to play it safe.

With this trail of thought, we identified that we are understocking because supermarkets prefer to play it safe to avoid losing money. That is the root cause. The solution, in this case, might be to be willing to share with the supermarket some of the losses for the products wasted and not sold, so that they are more confident to order more because they won’t have to bear the full loss.

Obviously, this is an oversimplified example, but it shows you that the idea is simple. Once you find a problem, dive deep to find why it is happening.

Lean Operations Management starts by Mapping Processes on Paper

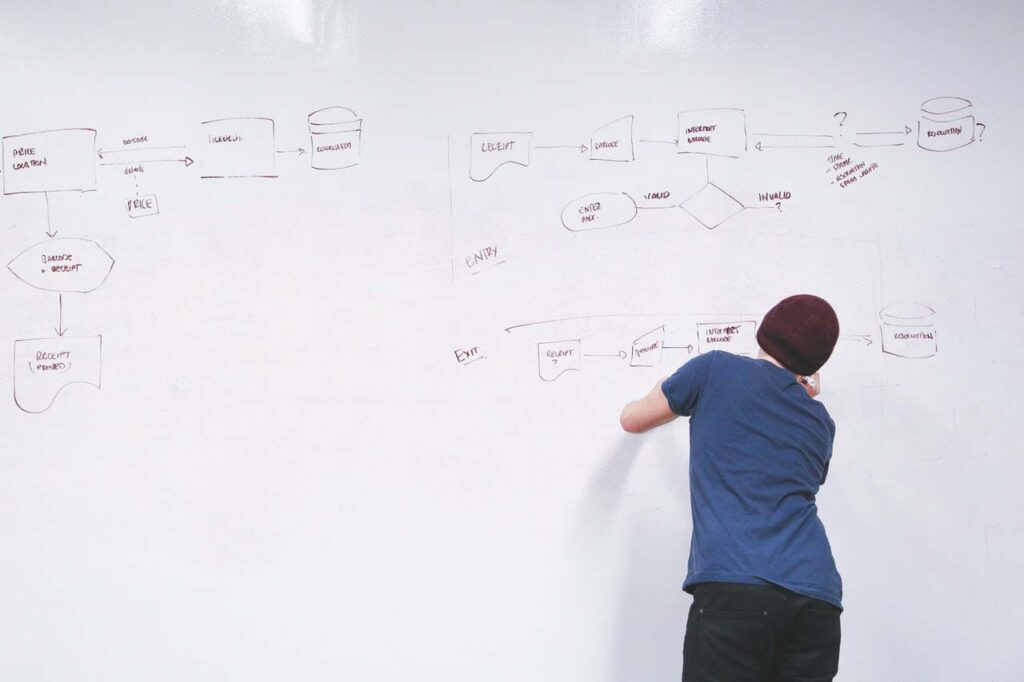

Flow charts are one of the most powerful tools in lean operations management. Before trying things in the field, you should at least spend some time to understand if they work on paper or not. Sometimes, workers are putting great effort, materials are of high quality, and yet you come up with poor results. The reason might be that the process itself is wrong: you are telling people to do the wrong things.

Therefore, spend time to represent a flow-chart of all your processes. Any lean operation manager should have a clear flow chart that details all the processes of the company.

There are various conventions to create these charts and covering them all would go beyond the purpose of this article, which is to prime you on lean operations management. However, there are generally two approaches: the standard flow chart (which applies also to disciplines outside of lean operations management), and the scientific management approach.

In a standard flow chart:

- Rectangle represents an activity, intended as a self-contained piece of work

- Diamond represents decision or condition, and it has two arrows going out of it with a label. For example, in the content of the diamond you may have “Does the package weight 300gr?” and then two arrows going out, one labeled “Yes” and the other “No”.

- Rounded rectangle represents a starting point for the process or an ending point of the process.

- Circle represents a reference to a sub-process or other process, but this is as not widely accept as the previous points.

Once you have mapped everything in a flow chart, you can start to see room for improvement also there, and then change the processes accordingly. A good idea is to try to rewrite your process on paper and see what a change in a task or another would imply.

A great tool to draw flow charts is Microsoft Visio.

What Does Lean Operations Management Do?

Sometimes when starting with lean operations management, people tend to forget the big picture and get excited about reducing waste. Instead, it is crucial to remember what is the goal of lean operations management, and keeps everything into perspective for that.

Lean operations managers direct the operations’ strategy, design its resources and processes, control how these processes are implemented and develop their capabilities. All of that should be kept in mind, for example reducing inventory can reduce flexibility, which is an important capability. If this is a capability that is crucial for your processes, maybe you need to find a way other than just reduce inventory.

Communicate, Communicate, Communicate

Lean operations management is really about communication. Improvements are incremental, which means they tend to be small and consistent. Since they are small, it is likely that a top manager won’t be able to see them because they are too much down in the hierarchy. Hence, lean operations management relies on input from everyone in the company.

To get great input from everyone in the company, you need to communicate your lean vision clearly. A good trick you can use there, and indeed most company do, is offer productivity bonuses in cash for employees that come up with solutions to make things better, faster, cheaper, more efficient, and generally speaking: leaner.

But remember, lean operations management is not something you do alone as a manager. It is an effort involving the entire company or plant.

Lean Operations Management in Summary

This primer on lean operations management presented the key pillars of lean operations and then discussed four levers that managers can use to put it to practice, plus explaining what the goal of lean operations management should be.

Lean is a flexible framework, and can surely find application in your company, even if not exactly as described here. As you might now, here on ICTShore.com we have extensive experience in IT, so if this is your field the natural next step for you should be to focus on IT operations management here.